Is LiTFSI the best choice to improve low temperature performance in HEV cells?

| Jerry Huang

Generally it is believed that the higher the proportion of hard carbon (above 15%) is coated to the anode of a li-ion battery, the better its conductivity. However, we must make it clear that the compaction of pure hard carbon pole pieces is about 1.15 g/cc. If more hard carbon is coated to the graphite material, the compaction density of the entire pole piece will be reduced (without increasing the space between the core material layers). It can only achieve 1.2g/cc at most. At the same time, the hard carbon may be compacted and the performance may not be fully utilized. Therefore, it is necessary to choose different ratio of hard carbon coating according to application scenarios.

It is common sense that the anode material is usually unevenly stressed and irregular. The larger the particle size of the material, the greater the internal resistance. Therefore, if hard carbon coating is used, although battery cycle life can be significantly expanded, its calendar life is relatively poor (battery cell capacity reduces greatly within storage of 6 months).

Is LiTFSI the best choice to improve low temperature performance in HEV cells?

Obviously, hard carbon-coated anode material is not enough to solve the pain points of poor performance at low-temperature; some other materials must be improved, such as electrolytes. Electrolytes are an important part of lithium-ion batteries, and they not only determine the migration rate of Li+ lithium ions in the liquid phase, but also play a key role in the formation of SEI film. At the same time, the existing electrolytes have a lower dielectric constant, so that lithium ions can attract more solvent molecules and release them during desolvation, causing greater system entropy changes and higher temperature coefficients (TCs). Therefore, it is important to find a modification method that has a smaller entropy change during desolvation, a lower temperature coefficient, and is less affected by the electrolyte concentration. Currently, there are two ways to improve low temperature performance through electrolytes:

- Improve the low-temperature conductivity of electrolytes by optimizing the composition of the solvent. The low-temperature performance of electrolytes is determined by the low-temperature eutectic point. If the melting point is too high, the electrolyte is likely to crystallize out at low temperatures, which will seriously affect the conductivity of electrolytes and ultimately lead to failure of the lithium battery. EC ethylene carbonate is an important solvent component of the electrolyte. Its melting point is 36°C. At low temperatures, its solubility is likely to decrease and even crystals are precipitated in electrolytes. By adding low-melting and low-viscosity components to dilute and reduce the EC content of the solvent, the viscosity and eutectic point of the electrolyte can be effectively reduced at low temperatures, and the conductivity of electrolytes can be improved. In addition, domestic and overseas studies have also shown that the use of chain carboxylic acid, ethyl acetate, ethyl propionate, methyl acetate, and methyl butyrate as the electrolyte co-solvent is beneficial to the improvement of the low-temperature conductivity of electrolytes and greatly improves the low temperature performance of the battery. Significant progress has been made in this area.

- The use of new additives to improve the properties of the SEI film makes it conducive to the conduction of lithium ions at low temperatures. Electrolyte salt is one of the important components of electrolytes, and it is also a key factor to obtain excellent low temperature performance. Since 2021, the electrolyte salt used on a large scale is lithium hexafluorophosphate. The SEI film that is easily formed after aging has a large impedance, resulting in poor low-temperature performance. Therefore, the development of a new type of lithium salt becomes urgent. Lithium tetrafluoroborate and lithium difluorooxalate borate (LiODFB), as lithium salts for electrolyte, have also brought high conductivity under high and low temperatures, so that the lithium ion battery exhibits excellent electrochemical performance in a wide temperature range.

As a new type of non-aqueous lithium salt, LiTFSI has high thermal stability, a small degree of association of anion and cation, and high solubility and dissociation in carbonate systems. At low temperatures, the high conductivity and low charge transfer resistance of the LiFSI system electrolyte ensure its low temperature performance. Mandal Et Al. has used LiTFSI as a lithium salt and EC/DMC/EMC/pC (mass ratio 15:37:38:10) as the basic solvent for electrolyte; and the result showed that the electrolyte still has a high conductivity of 2mScm-1 at -40°C. Therefore, LiTFSI is regarded as the most promising electrolyte that can replace lithium hexafluorophosphate, and is also regarded as an alternative for the transition to an era of solid electrolytes.

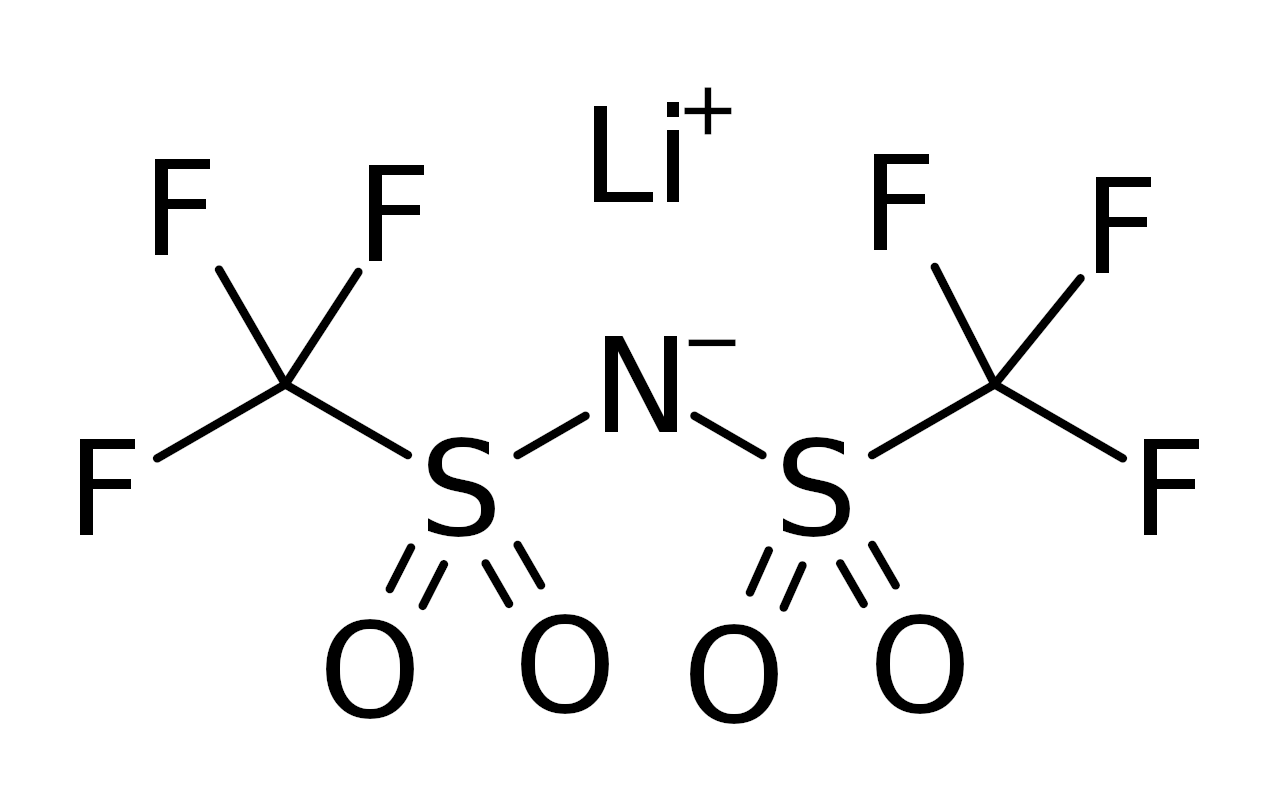

According to Wikipedia, Lithium bis(trifluoromethanesulfonyl)imide, often simply referred to as LiTFSI, is a hydrophilic salt with the chemical formula LiC2F6NO4S2. LiTFSI is a white crystal or powder that can be used as an organic electrolyte lithium salt for lithium-ion batteries, which makes the electrolyte showing high electrochemical stability and conductivity. It is commonly used as Li-ion source in electrolytes for Li-ion batteries as a safer alternative to commonly used lithium hexafluorophosphate. It is made up of one Li cation and a bistriflimide anion. Because of its very high solubility in water (> 21 m), LiTFSI has been used as lithium salt in water-in-salt electrolytes for aqueous lithium-ion batteries.

LiTFSI can be obtained by the reaction of bis(trifluoromethylsulfonyl)imide and lithium hydroxide or lithium carbonate in an aqueous solution, and the anhydrous can be obtained by vacuum drying at 110 °C: LiOH + HNTf2 → LiNTf2 + H2O

Lithium bis(trifluoromethylsulfonyl)imide can be used to prepare electrolytes for lithium batteries and as a new Lewis acid catalyst in rare earth; it is used to prepare chiral imidazolium salts by anion replacement reaction of corresponding trifluoromethanesulfonates. This product is an important fluorine-containing organic ion compound, which is used in secondary lithium batteries, super capacitor Chemicalbook, aluminum electrolytic capacitors, high-performance non-aqueous electrolyte materials and as new high-efficiency catalyst. Its basic uses are as follows:

- Lithium batteries

- Ionic liquids

- Antistatic

- Medicine (much less common)

However, an R&D engineer from China once said: “LiTFSI is mainly used as an additive in current electrolytes and will not be used as the main salt alone. In addition, even if it is used as an additive, the formulated electrolyte has better performance than other electrolytes. LiTFSI Electrolyte is much more expensive than usual types of electrolytes, so LiTFSI is not added, if there is no special requirements on electrolyte performance."

It is believed that in some application scenarios, there are substantial requirements for high-power batteries, scenarios such as electric forklifts and AGVs. As concerns on durability and attributes of production tools, it is also necessary to solve the problems of cycle life and low-temperature performance at one time. Therefore, research and development on next-generation electrolytes will continue. But it is still a multi-dimensional concern and competition of performance, cost, and safety; and the markets will eventually make their own choices.

References:

- Zheng, Honghe; Qu, Qunting; Zhang, Li; Liu, Gao; Battaglia, Vincent (2012). "Hard carbon: a promising lithium-ion battery anode for high temperature applications with ionic electrolyte". RSC Advances. Royal Society of Chemistry. (11): 4904–4912. doi:10.1039/C2RA20536J. Retrieved 2020-08-15.

- Kamiyama, Azusa; Kubota, Kei; Nakano, Takeshi; Fujimura, Shun; Shiraishi, Soshi; Tsukada, Hidehiko; Komaba, Shinichi (2020-01-27). "High-Capacity Hard Carbon Synthesized from Macroporous Phenolic Resin for Sodium-Ion and Potassium-Ion Battery". ACS Applied Energy Materials. American Chemical Society. 3: 135–140. doi:10.1021/acsaem.9b01972.

- Khosravi, Mohsen; Bashirpour, Neda; Nematpour, Fatemeh (2013-11-01). "Synthesis of Hard Carbon as Anode Material for Lithium Ion Battery". Advanced Materials Research. 829: 922–926. doi:10.4028/www.scientific.net/AMR.829.922. S2CID 95359308. Retrieved 2020-08-15.

- Goriparti, Subrahmanyam; Miele, Ermanno; De Angelis, Francesco; Di Fabrizio, Enzo; Proietti Zaccaria, Remo; Capiglia, Claudio (2014). "Review on recent progress of nanostructured anode materials for Li-ion batteries". Journal of Power Sources. 257: 421–443. Bibcode:2014JPS...257..421G. doi:10.1016/j.jpowsour.2013.11.103.

- Irisarri, E; Ponrouch, A; Palacín, MR (2015). "Review-Hard Carbon Negative Electrode Materials for Sodium-Ion Battteries". Journal of the Electrochemical Society. 162: A2476. doi:10.1149/2.0091514jes.

- Dou, Xinwei; Hasa, Ivana; Saurel, Damien; Vaalma, Christoph; Wu, Liming; Buchholz, Daniel; Bresser, Dominic; Komaba, Shinichi; Passerini, Stefano (2019). "Hard carbons for sodium-ion batteries: Structure, analysis, sustainability, and electrochemistry". Materials Today. 23: 87–104. doi:10.1016/j.mattod.2018.12.040